The Monastery of Saint Nektarios in Doridos, Greece

Sister Joanna leads the sisters of this monastery in making their own cheese.

From their small herd of 8 cows, the sisters make cheese daily to improve their self sufficiency

and, perhaps, just because they love making cheese from their own special herd.

With the aid of supplies from Ricki's shop and a few exchanges in emails from our technical guy Jim, these sisters have managed to develop some great skill in making their own cheese for the monastery. Sister Joanna has been kind enough to send the photos and a description of their process as shown below.

The cheese we made in the photos is a Greek cheese called Graviera. This cheese is usually made from sheep's milk but we decided to try it with cow's milk and its just as tasty. Its a cheese with a piquant flavor, similar to Romano cheese and its melts really well..The longer its cured the tastier it gets. We usually wait 5-6 months before its eaten. Its a fabulous cheese especially for melting.We really like it here in our monastery. Sister Joanna

Here are the monastery cows, Lucy, Sissy, April, Rafaela, and Smora, ready to milk and the collected milk on its way to becoming cheese. They begin with 8 gallons of fresh milk each time they make cheese.

As seen here, the cheese room is quite efficient, well layed out, and very easy to clean.

The milk comes in, is transferred to the vat where culture is added for ripening. After a short ripening time for the bacteria to work, the rennet is added and then they must wait for the solid curd to form.

Once the curd is firm enough it will be cut to release the whey. Then it will be cooked and stirred until dry enough for molding and pressing. While waiting for this process, Sister Joanna makes Fromagina with Ricki's special cultures in the Yogotherms to keep it all warm.

When the curds have been cooked dry enough for the Graviera they are transferred to the cheescloth lined mold for pressing. Meanwhile the Fromagina is ripening in the Yogotherms.

The cheese will now be pressed to consoldiate the cheese into the final Graviera. It will be removed from the press, unwrapped, turned, rewrapped, and pressed again. This will be done several times, increasing the pressure each time until the cheese is well formed as you see to the right.

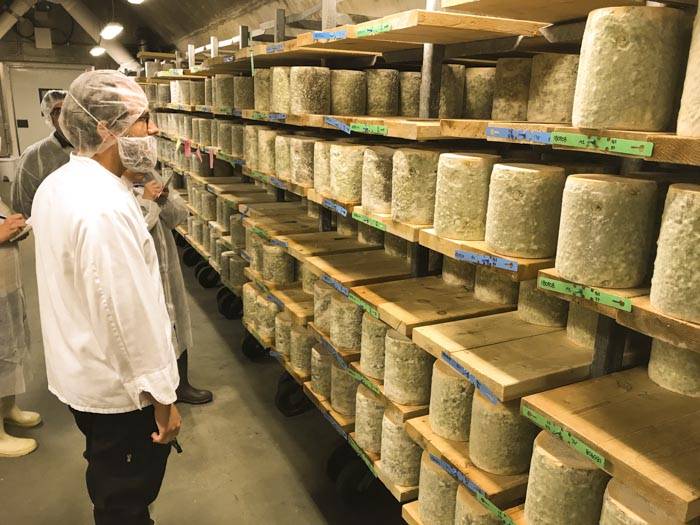

As you can see here the sisters have been quite productive with the bounty from their cows.

In the true monastery tradition, they work to produce what they need.