Allow the curds to settle and drain, keeping the draining space at 68-74F (warmer or cooler will cause problems with the resulting cheese).

To assure a good draining, the cheese will need to be turned in the molds. This is done by placing a second draining mat on top followed by another turning board (as mentioned in the prep above). Then carefully lift the entire assembly carefully and with one hand on top and the other on the bottom (firmly) flip the cheese over quickly. If you have big enough hands though, it is best to clamp the form and drain mats between both boards with each hand for the turn.

Note: This will be the most challenging time for this make, and the point where everything could go south rather quickly. I suggest practicing this several times before you add the curds.If there are any openings the curd will try to escape the form. Once you have done this a few times, you will understand.

Commercially, this flipping is all done with machines and many forms ganged together. You should know I have done well over a hundred batches successfully.

It is best to make the first turn shortly after the curd is ladled (within 30 minutes). This will keep it from falling too far in the mold and breaking. Repeat the turning as above at 2-3 hour intervals to even out the moisture release.

Keep the draining space at 70-74F to encourage whey release. The initial draining and turning is normally about 14-20 hours. I usually let the Brie drain overnight. It should show a significant slowing of whey release towards the end. The taste of the whey at this point should have a very noticeable acidity to it compared to that first running out during draining. It is a good practice to taste the whey and curds throughout the process for future reference.

We do not salt the curds until the draining slows because the culture needs to keep working and the draining whey would take much of the salt with it.

The cheese will drain down to about 1/3 the original curd height. During this time, flip the cheese in their forms several times to make sure the draining is even. The cheese will become firmer and the turning easier as it drains.

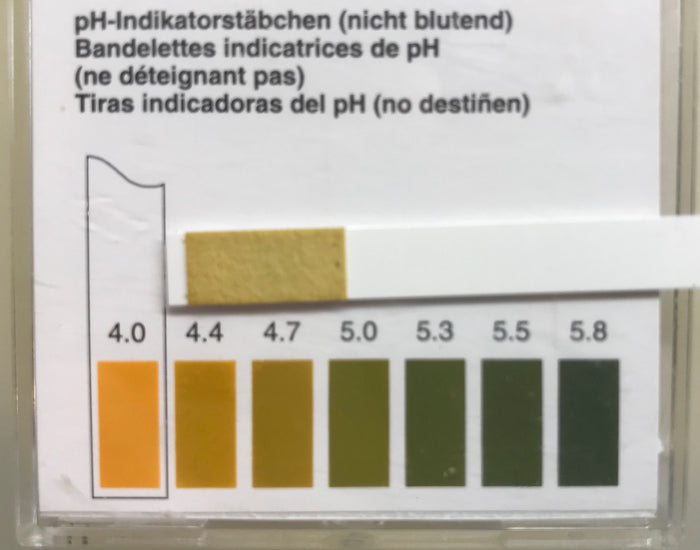

If you have pH test strips they should show a pH of about 4.6 when done