My husband and I discovered artisan cheese two summers ago at a farmer's market in Londonderry, Vt. There we bought a Camembert-style soft-ripened cheese made from sheep's milk that we simply fell ...

It has been a long road traveling in many directions, sometimes simultaneous, sound familiar. I began in pre-med but wound up teaching environmental biology which led to 25+ years of photographing ...

Andrea is a new startup cheese maker and what drew her to my attention was the number of progressive questions she kept asking at our online tech site. These questions clued me to the fact that she...

Sister Joanna leads the sisters of this monastery in making their own cheese. From their small herd of 8 cows, the sisters make cheese daily to improve their self sufficiency and, perhaps, just bec...

This is true Home or Farmstead cheese making on a small scale. Just to get started we would like to show you the before and after photos of our six hundred sq. foot facility. As you can see we got ...

Paul Lacinski and Amy Klippenstein

These are the real cheese makers, the four legged ones that provide that fabulous milk we use. No, not Paul and Amy, we are talking about the girls in the meadow.

Greetings from New Zealand. I was born in Cape Town, South Africa in July 1951, so that makes me an 'old bugger.’ I am trained as a toolmaker and worked for many years in the Aerospace, Research &a...

Reverand Yoginatha Swami from Kauai Hindu Monastery. The monastery web site is a wonderful place to watch the progress as these monks construct this world class temple.

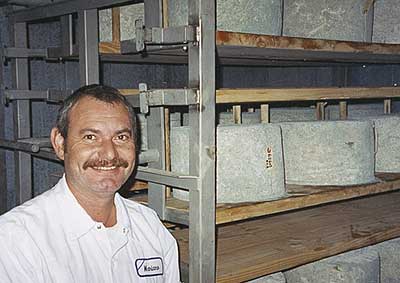

A visit with Mariano to see how he makes that famous bandaged cheddar. After meeting at the American Cheese Society convention in San Francisco, we headed to the Fiscalini Farm in Modesto for a vis...

John & Janine Putnam from Thistle Hill Farm in North Pomfret VT. Producing 'Tarentaise' Vermont Alpine Cheese. An aged alpine raw milk cheese handmade on the Putnam family farm. The cheese is m...

Carol Lively and her daughter Christina Lively Spring Farm Rowe MA. True Home/Farmstead cheese making on a small scale. The Lively's have a small farm in western Massachusetts where Carol and her d...

All you need is milk

Cheese Making Kits

Discover the joy of cheese making with our all-inclusive kits, perfect

for crafting a variety of cheese. Whether you're a novice or looking to surprise someone special, these kits offer a simple and enjoyable way make cheese at home.

Cheese Making Supplies

Recommended Products

Cheese Making Recipes